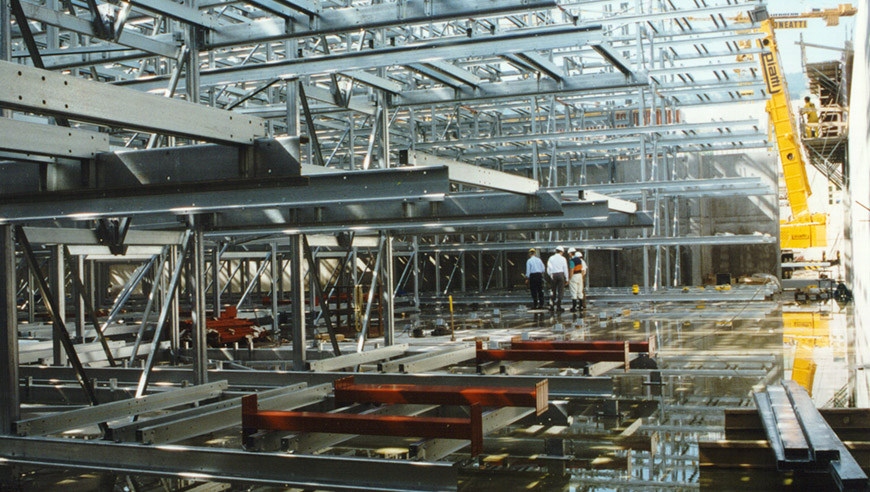

General planning of a modern distribution centre with optimum automation.

Estée Lauder AG specialises in the distribution of specialist products for the travel retail business, and supplies approximately 4,500 articles to duty-free shops in more than 100 countries. To ensure its ability to deliver worldwide and allow for the flexible expansion of its storage capacity, the company commissioned the construction of a new distribution centre in the Swiss town of Lachen. On the basis of a feasibility study, as the general planner and contractor, IE Technology planned and implemented an efficiently designed industrial building with state-of-the-art order picking and high-bay warehouse technology.

The challenge.

The experts from IE Technology were commissioned with the development of an integral and multifunctional industrial construction concept. In addition to the efficient completion of the work, from the goods receipt, storage and order picking to the shipment, it was also necessary for the possibility to increase the warehouse capacity on a flexible basis without structural measures to be taken into account. Part of the implementation planning was the development of a new strategy for the automation of the flow of goods and the storage, so as to untangle these processes and make them considerably more efficient. Adding to the difficulties in this context was the necessity to comply with the international requirements of the group in the fields of architecture, safety and environmental compatibility.

The success factors.

In a record 52 weeks, the experts at IE Technology planned and implemented a brightly-lit and elegant distribution centre in the shape of an open customs warehouse. This is home to the incoming goods, the order picking and shipping departments, as well as technical facilities, the administration department and also a cafeteria. The heart of the new location is a high-bay warehouse more than 100 metres in length with enough space for some 12,800 pallets, which has been divided into four zones for optimum order picking and equipped with a specialist conveyor system. The quality of the order picking is further ensured by a two-stage weight control system. Thanks to the logistics strategies and efficient logistics infrastructure developed by IE Technology, it was possible for an additional volume of 30% to be handled within just one year.

1 year

from the feasibility study to the completion of the new distribution centre

12,800

pallet spaces and a total storage capacity of nine levels

30%

increased volume thanks to optimum logistics strategies and efficient infrastructure

100

metre-long high-bay warehouse with the latest automation technology

4

zones and two-stage weight control for superior order picking quality

100%

flexibly extendible storage capacity without the need for structural measures

Our industry specialists – your direct contact for IE Technology.

Contact

Thomas Rieger

Managing Director IE Technology Zurich

Telephone number

+41 44 389 86 09

E-mail

t.rieger@ie-group.com

Other successful IE Technology projects in electrical technology and high-tech production.

IE TECHNOLOGY

Planning and implementation of new head office for the company Anklin AG.

IE TECHNOLOGY

Feasibility study and hygiene concept for a new high-tech production location, HLM Leuthold Mechanik AG.